![]()

Receiver Finishes: Anodized vs Cerakote vs DIY Paint Job

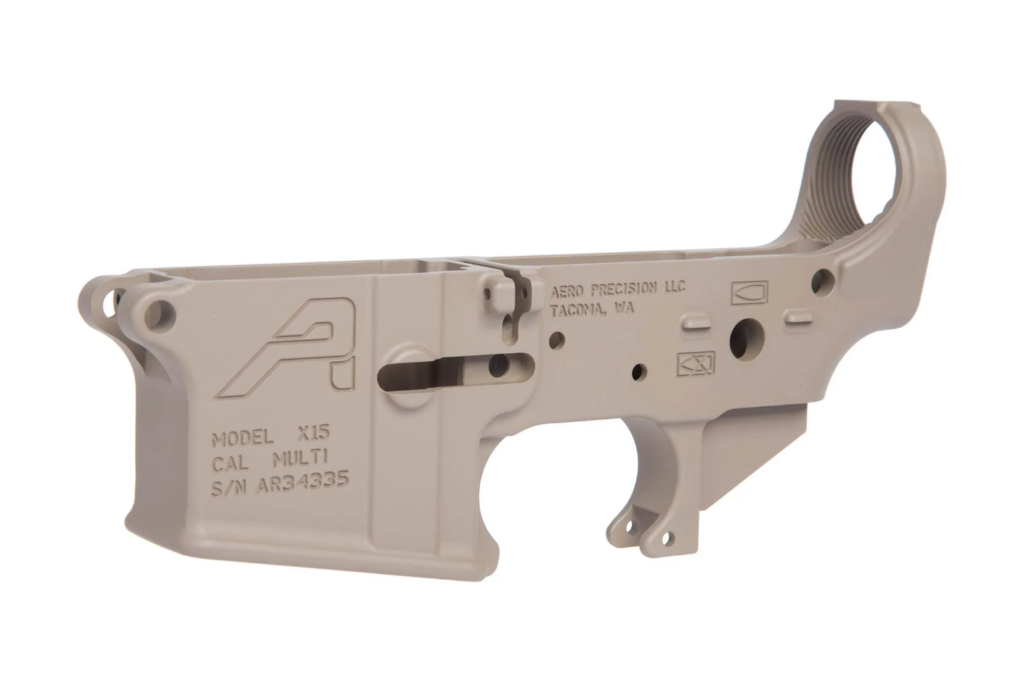

Have you gotten a new stripped lower receiver and want to personalize it? There are many options for you to finish the receiver. There is an anodized finish, Cerakote, and the classic do-it-yourself paint job.

Which one is best for your weapon? Which will help you express your personality the clearest? Let us look at the differences and find the one that suits you and your weapon best. Let us dive into Anodized vs Cerakote vs DIY Paint Job.

Anodized Lower Receiver Finishes

Anodizing is also sometimes referred to as a hard coat. Anodizing is the process that turns metal into a corrosion-resistant coating for your receiver. There are many benefits to anodized finishes. This gives the coating increased strength, durability, and corrosion resistance.

This is important if you are planning to be using your weapon in varying outdoor environments. This gives you the freedom to focus on the task at hand instead of worrying about things like immersing your weapon, dinging it on rocks, and the general wellbeing of your firearm.

The anodized outside also assists in keeping the internal parts of your AR-15 well cared for. Anodization helps keep the weapon cooler, requires less oil to be put into the weapon, and cuts down on internal friction.

Each of these improvements, all because you have an anodized lower receiver, increases the time in between services of your weapon. You will be saving time and money by not having to replace parts of your weapon, internal and external, for longer periods.

Cerakote Lower Receiver Finishes

Cerakoting is the name of the process of applying a liquid ceramic coat to the outside of your firearm. The firearm is then subject to high heat to harden the ceramic coat. This hardened coat makes the weapon safe, providing extreme tolerance levels to outside elements.

Cerakote dries well and creates a thin coating, so you do not have to worry about it complicating putting your weapon back together. This coating can also help with overall performance of your weapon and prolong the durability of the internal parts. This is because cerakoting creates resistance against friction and heat while in use.

The benefits of Cerakote are like those of an anodized finish. Cerakote prevents corrosion, improves performance, and reduces overall wear and tear. You can completely cover your AR-15 in Cerakote and be fully confident that it will be protected from outside elements. It is extremely unlikely that the coating will be blemished by rocks, rain, or other outside influences.

Another benefit of Cerakote is that the coatings are customizable. This means that if you wish to add a camouflage look to your weapon, you can! This gives you the freedom to create a weapon that is uniquely yours.

Also specific to a Cerakote covering, you can have all parts of your weapon coated, including all internal pieces. Many people send off the bolt to be coated. This improves the overall durability of your weapon. It can even improve the overall accuracy of your weapon because it creates a tighter tolerance. This is something important to consider when thinking about putting a finish on your lower receiver or on the entire weapon.

DIY Paint Job Finishes

The easiest way to give your weapon a DIY paint job is to pull out the spray on coatings and go from there. You can use different textures and covers to help you create a unique design. There are other ways to give your AR-15 a do-it-yourself paint job, but those have been known to cost more since you must have multiple pieces of equipment, and the paint used with those can give off chemicals to the air.

You do not want to have an issue breathing in those chemicals when you are just trying to customize your weapon!

DIY paint jobs can protect your weapon from corrosion-causing chemicals, and it can help protect your weapon from scratches. Having this extra layer also helps make your weaponless prone to rust. This is the best way to customize your lower receiver and it is the cheapest option when looking to protect against corrosion and rust while also making it look special to you.

The problem with DIY painting is that it can either turn out looking amazing, or it will look like a 3-year-old child did it for you. This can lower the resale value of the weapon, so you want to keep this in mind if you are planning to paint your weapon or your lower receiver.

If you only paint the lower receiver and not the entire weapon, you can easily replace the lower receiver with a new one before selling, or the new owner can purchase it if they do not like your paint job.

Which is Better?

Which way of painting your lower receiver is the best? It all depends on what you are looking for. If you are wanting something to protect the weapon, any of the three will help. Anodizing it can create a barrier where friction will not hurt your weapon as much. It also can be used only on the lower receiver, saving your weapon some wear and tear.

The Cerakote covering can be used on all pieces of the weapon, though, saving the entire weapon from corrosion, blemishes, and other wear and tear. Cerakote would be the best option for protecting your weapon from all elements of destruction, but it can also be a bit pricier since you cannot do it by yourself and you must use more Cerakote to cover the entire weapon, internally and externally.

The do-it-yourself version is one that will provide the most fun, but it does not provide the most protection. It can still help protect against rust and corrosion, but that is about it.

The paint job can lower the overall resale value of your weapon. It will not hurt you if you are planning to keep the weapon forever, but it could hurt if you want to trade it later.

Whatever you decide, your weapon will be protected against some elements and will help you preserve your weapon and keep it in working order. Whatever you choose, have fun with it!

Check out our other gun guides as well as our latest gun bag reviews.